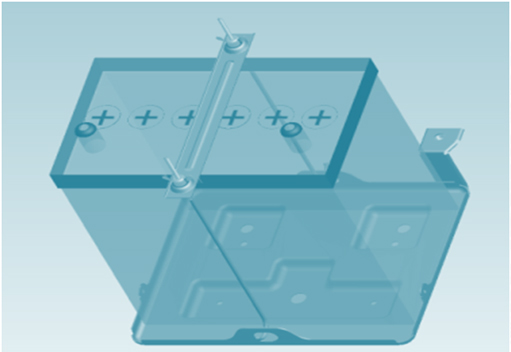

Automotive Battery Tray Assembly Cost Reduction

Automotive Battery Tray Assembly Cost Reduction & Improving end user satisfaction

Scope: To reduce the Control Box BOM cost by 20% over the present Product Cost

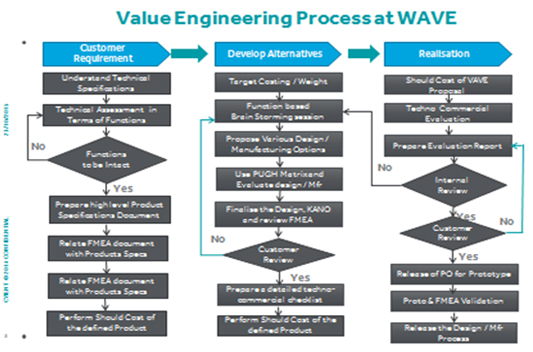

Tools: ProE, ANSYS, VAVE Process

Timelines: Within 90 days from the kick off date

Results: Product cost reduced by more than 20% from the present cost with issue resolution

At Vigrotek, we follow a very structured process for Value Engineering completely focusing on end Customer satisfaction.

Product User / End Customer voice capture is the main input for this program

The Engineers at Vigrotek have experience in the area of Electronics, Mechanical and electrical Design, Analysis and Supplier development for Prototypes

Value Addition

- Design simplification

- Resolving Serviceability issue

- Spare part design simplification

- Elimination of Design Waste

- Improved aesthetics

Effort Taken

Total effort of 300 Hours which included

- Design

- VAVE Process definition

- Analysis using ANSYS

- Design improvement

- Part availability coordination with suppliers

- Assembly